Author: Stian Mydland

When running compositional reservoir simulations, it is always good practice to quality check that the equation of state (EOS) model developed in a standalone PVT package is exported correctly to the simulator. This is achieved by taking the fluid related output from e.g. CMG GEM, Eclipse 300, or Sensor, and compare it with a PVT-simulator e.g. PhazeComp, PVTsim, or WinProp.

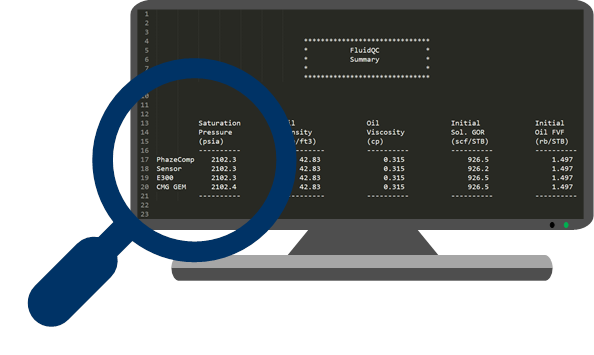

There are five main fluid properties that should be checked to verify that your fluid model is correct. These are; saturation pressure, viscosity, density, solution GOR/OGR (oil/gas), and formation volume factor. To get the properties of both the oil and solution gas (or gas with solution condensate) one should perform the quality check at the initial saturation pressure. A rule of thumb is that the numbers should match to at least the fourth digit.

Performing a quality check of the fluid properties can be done using a single grid block simulation with a single time step. The simulator will then yield a small output file which is easy to read through. Note that many of the fluid parameters must be requested by a printout keyword in E300, GEM, and Sensor, to have them printed to the output file. To simplify further application of the fluid model, we recommend importing the EOS and composition to the simulator by including them in separate files. After the quality check is performed, the files contain a correctly interpreted fluid model which can be readily included in any simulation case, i.e. input syntax is verified and the fluid properties are correct.

All three simulators have different input formats, and there are some potential pitfalls when importing an EOS. The 132-character limit in E300 may cause simulation errors if the data for the component properties in the EOS are provided on a single line. One can avoid this by providing the data in a single column following the respective EOS keyword. Units may also cause errors. In GEM, the unit of critical pressure is atmosphere, and critical temperature is Kelvin, even though field units are specified for the simulation.

The EOS formulations differ between the three simulators. The Peng-Robinson (PR) EOS in E300, activated by the keywords EOS PR in the “RUNSPEC” section, is the original EOS formulation from 1976. The more commonly used 1979 version is activated by the PRCORR keyword in the PROPS section. In GEM, the Soave-Redlich-Kwong (SRK) EOS, activated by the keywords MODEL SRK in the “Component Properties” section, is a modified version by Graboski and Daubert (1979). This version may yield different saturation pressures compared to the original (and more commonly used) 1972 SRK version. However, if the user wants the 1972 SRK EOS, CMG has an undocumented keyword IRKMOD 0 in the “I/O Control” section which turns this on. In Sensor, the default EOS is PR1979 which requires no keyword for activation, but PR1977, and SRK, may also be used by explicitly typing either of the two after the “PVTEOS” keyword.

When comparing the initial solution-GOR in the different simulators, there might be a slight difference between them. The reason for this is that E300 and Sensor assumes a gas Z-factor equal to 1 at standard conditions (STC), but GEM calculates it from the EOS. For most practical purposes, Z-factor equal to 1 at STC is a valid assumption, but the difference in calculated GOR may cause confusion when comparing them.

A reservoir simulation model is often complex with large amounts of data that the engineer(s) must handle. We recommend taking the time to QC that the simulator is honoring your fluid model properly before running any simulations.

Learn more about our consulting capabilities

###

Global

Curtis Hays Whitson

curtishays@whitson.com

Asia-Pacific

Kameshwar Singh

singh@whitson.com

Middle East

Ahmad Alavian

alavian@whitson.com

Americas

Mathias Lia Carlsen

carlsen@whitson.com

About whitson

whitson

supports energy companies, oil services companies, investors and government

organizations with expertise and expansive analysis within PVT, gas condensate

reservoirs and gas-based EOR. Our coverage ranges from R&D based industry

studies to detailed due diligence, transaction or court case projects. We help

our clients find best possible answers to complex questions and assist them in

the successful decision-making on technical challenges. We do this through a

continuous, transparent dialog with our clients – before, during and after our engagement.

The company was founded by Dr. Curtis Hays Whitson in 1988 and is a Norwegian

corporation located in Trondheim, Norway, with local presence in USA, Middle

East, India and Indonesia