Author: Mathias Lia Carlsen

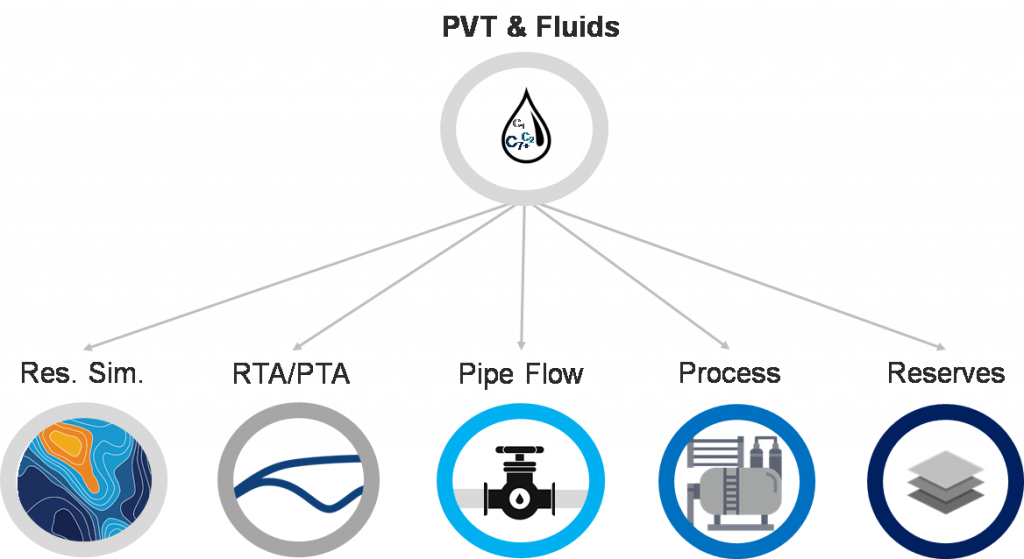

PVT and fluid characterization are fascinating! Unlike other parameters needed for petroleum engineering calculations, PVT properties have an impact on essentially every discipline in the petroleum domain. Just think about it: whether you do engineering related to reservoir, production, pipeline, facility or process you need PVT. Even geologists need PVT to calculate original oil or gas in place (OOIP = HCPV/Bo, OGIP = HCPV/Bgd). And if you think about it, it makes a lot of sense; E&P companies sell petroleum fluids – oil and gas – to make a living … not rocks, pipe or separators!

Since PVT properties are necessary for essentially every part of the oil and gas value chain, you would think that it is trivial to use the same fluid description/model from the reservoir to sales. Turns out it is not. Often different fluid models are used to describe the same physical fluid at different points throughout the production system. This is partly the software-vendors fault, as different vendors have different “go-to” fluid models, and different models are necessary to simulate different parts of the value chain. In addition, in the petroleum industry, we tend to work in “silos”, where reservoirs engineers work with other reservoir engineers, geologists with other geologists and so on. This makes it challenging to incorporate cross-disciplinary consistency.

At the SPE Workshop on Complex Reservoir Fluids that was arranged in Galveston, TX, earlier this year, we proposed one way of incorporating cross-disciplinary fluid consistency throughout an organization. The details are summarized in the presentation attached. In short, it involves

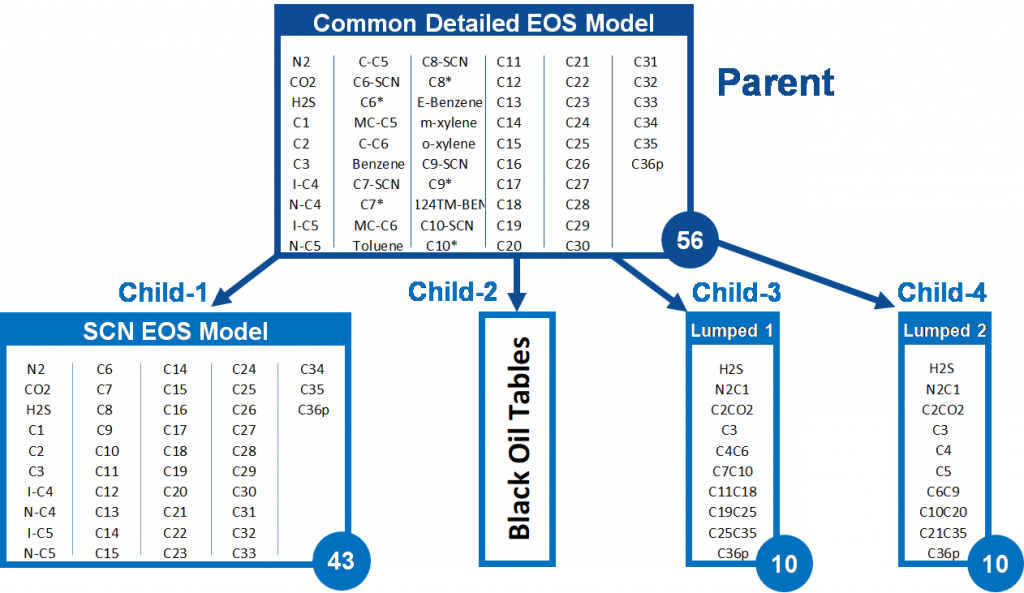

- Creating a “parent” EOS model: a common EOS model, with the entire, detailed compositional slate with non-hydrocarbon compounds (N2, CO2, H2S), all single-carbon number components (C1, C2, C3, … C36+ etc.) and all the isomers measured in the laboratory (benzene, toluene etc.). This EOS model should be developed by incorporating all available, good quality PVT data from a field – sometimes 100s of fluid samples!

- Derive “children” EOS model tailored for specific applications: the degree of compositional resolution that is required for different petroleum engineering calculations may vary a lot, e.g. for pressure depletion, a black oil table (“child”) derived from the “parent” EOS may be sufficient. For miscible gas injection, where capturing the true MMP is important (C/V mechanism), a pseudoized EOS model (“child”) derived from the “parent” EOS may be necessary. One properly tuned “parent” EOS model doesn’t only make the lumping exercise simpler, but it also allows for consistent delumping of models to higher resolution models!

But why is fluid consistency important? Let’s say you use two different EOS models to model different segments of the reservoirs flowing into the same wellbore, or that go to the same surface facility for that matter. First: what EOS model should you use in the wellbore or at the surface where these wellstreams mix? Second: the thermodynamic properties of one component will be different depending on what model you use, i.e. for the same composition, the equilibrium K-values from a flash calculation will be different – which does not make much physical sense (as it is the same physical fluid)! These PVT model inconsistencies can be a serious problem resulting in mass, molar, and volumetric material balance errors in key applications such as field development and design, short term and long-term production optimization and decision support.

Since the fluid that flows from the reservoir is physically the same throughout the production system, we believe it should also be described by the same fluid model throughout the entire production system, all the way from reservoir to sales.

Learn more about our consulting capabilities

###

Global

Curtis Hays Whitson

curtishays@whitson.com

Asia-Pacific

Kameshwar Singh

singh@whitson.com

Middle East

Ahmad Alavian

alavian@whitson.com

Americas

Mathias Lia Carlsen

carlsen@whitson.com

About whitson

whitson supports energy companies, oil services companies, investors and government organizations with expertise and expansive analysis within PVT, gas condensate reservoirs and gas-based EOR. Our coverage ranges from R&D based industry studies to detailed due diligence, transaction or court case projects. We help our clients find best possible answers to complex questions and assist them in the successful decision-making on technical challenges. We do this through a continuous, transparent dialog with our clients – before, during and after our engagement. The company was founded by Dr. Curtis Hays Whitson in 1988 and is a Norwegian corporation located in Trondheim, Norway, with local presence in USA, Middle East, India and Indonesia