Author: Ahmad Alavian

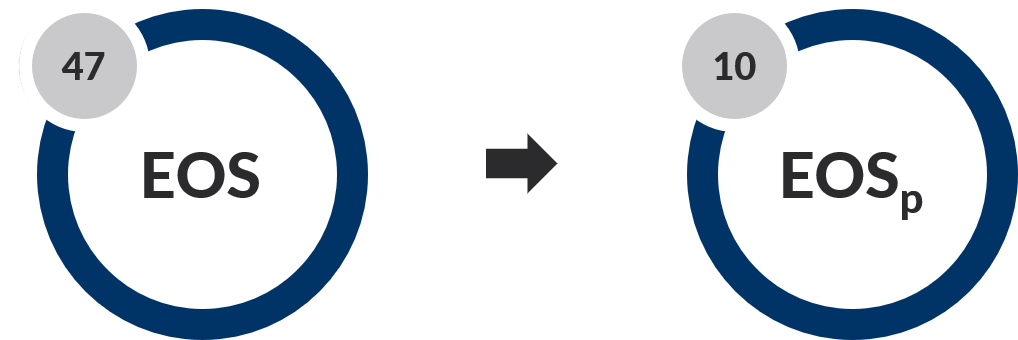

Did you develop a detailed equation of state (EOS) model and you do not know how to lump the components? Here is how we do it!

The EOS model must provide an accurate prediction of phase and volumetric behavior of relevant mixtures flowing through a given system being modeled. Properties of density, viscosity, phase volume split and phase compositions are used in model calculations. Depending on the range of p-T-z space, the EOS model required may contain different numbers of components – e.g. nine for reservoir simulation, six for flow assurance, and 22 for process modeling. It is recommended to have a single, detailed EOS model that describes all PVT data throughout the range of p-T-z for the entire petroleum system. The detailed EOS model can have 20-40 components, depending on the software used and what a company practices in EOS model building.

To obtain a process-specific pseudoized EOS model (typically with less than 12 components), the relevant p-T-z conditions must be well defined for a particular application. The choice of lumped components used in a pseudoized EOS is process dependent – i.e. dependent on the range of pressure, temperature, and composition being modeled.

Our approach to component lumping and development of a pseudoized EOS has the following steps:

- Start with an accurate, detailed EOS model and at least one, but preferably a set of fluid compositions described with detailed EOS component slate.

- Define the range of p-T-z relevant to the processes being modeled, including a range of samples that cover the low-to-high gas-oil ratios (GORs) of relevant fluids.

- Calculate all relevant PVT properties (densities, viscosities, compositions, phase fractions) with the detailed EOS for the entire range of relevant p-T-z defined in step (2).

- Input detailed EOS-calculated PVT results in step (3) as “data” into the EOS-based PVT program.

- Specify the desired number (Nx) of components in the pseudoized EOS, and any constraints on the lumping strategy.

- Define the total lumping combinations. Generate all possible lumping cases.

- For each lumping scheme, use a reliable method to calculate pseudoized EOS average pseudo-component properties based on a single “averaging” composition zi.

- For each new lumping scheme, use all of the PVT “data” defined in step (3) and calculate a weighted measure of model accuracy – e.g. a weighted root mean square (RMS).

- Identify the lumping scheme(s) that give the best model match (lowest RMS).

- The process can be repeated using different averaging methods and different averaging composition zi in step (8).

- Evaluate, in detail, the PVT calculations of the final pseudoized EOS model(s) with the lowest RMS, compare with results from the original detailed EOS model. Plot and compare tables of key data.

- If MMP is of particular importance (or other more-complex calculations than could be included in the global search because of CPU limitations), select a subset of the scenarios from the global search (100-500) with lowest RMS values for PVT predictions. Run MMP calculations for these scenarios and compare with MMP from the detailed EOS model, to select the best combination of PVT fit (low RMS) and prediction accuracy of the MMP.

More technical details can be found in SPE-170912: Global Component Lumping for EOS Calculations.

Learn more about our consulting capabilities

###

Global

Curtis Hays Whitson

curtishays@whitson.com

Asia-Pacific

Kameshwar Singh

singh@whitson.com

Middle East

Ahmad Alavian

alavian@whitson.com

Americas

Mathias Lia Carlsen

carlsen@whitson.com

About whitson

whitson supports energy companies, oil services companies, investors and government organizations with expertise and expansive analysis within PVT, gas condensate reservoirs and gas-based EOR. Our coverage ranges from R&D based industry studies to detailed due diligence, transaction or court case projects. We help our clients find best possible answers to complex questions and assist them in the successful decision-making on technical challenges. We do this through a continuous, transparent dialog with our clients – before, during and after our engagement. The company was founded by Dr. Curtis Hays Whitson in 1988 and is a Norwegian corporation located in Trondheim, Norway, with local presence in USA, Middle East, India and Indonesia