Author: Bilal Younus

The term “single phase labeling” means to determine whether the given total composition zi (in a specific grid cell in the model) exists as single-phase “oil” or single-phase “gas” when the grid cell pressure is higher than the saturation pressure ps = f(zi,T), where T is the temperature in the model.

A compositional simulation model would require calculating ps(zi,T) to accurately identify the phase in every grid cell such that oil being a bubble point pressure and gas being a dew point pressure. However, calculating ps(zi,T) for every grid cell at every time step could increase the simulation run time depending on how the saturation pressure calculation algorithm is set up in the simulator. Therefore, simulators generally use other methods for single-phase labeling, which may not be as accurate as saturation pressure or EOS-based phase labeling.

For example, for phase labeling in single-phase grid cells, E300 simulator uses Li method as default option. It computes an approximate (pseudo) critical temperature using Li correlation (TcLi) of the grid cell composition zi using the following equation as a function of zi, critical temperature of each component Tci and critical volume of each component Vci,

$${T_c}^{Li}=\frac{\sum{T_{ci}V_{ci}z_i}}{\sum{V_{ci}z_i}}$$

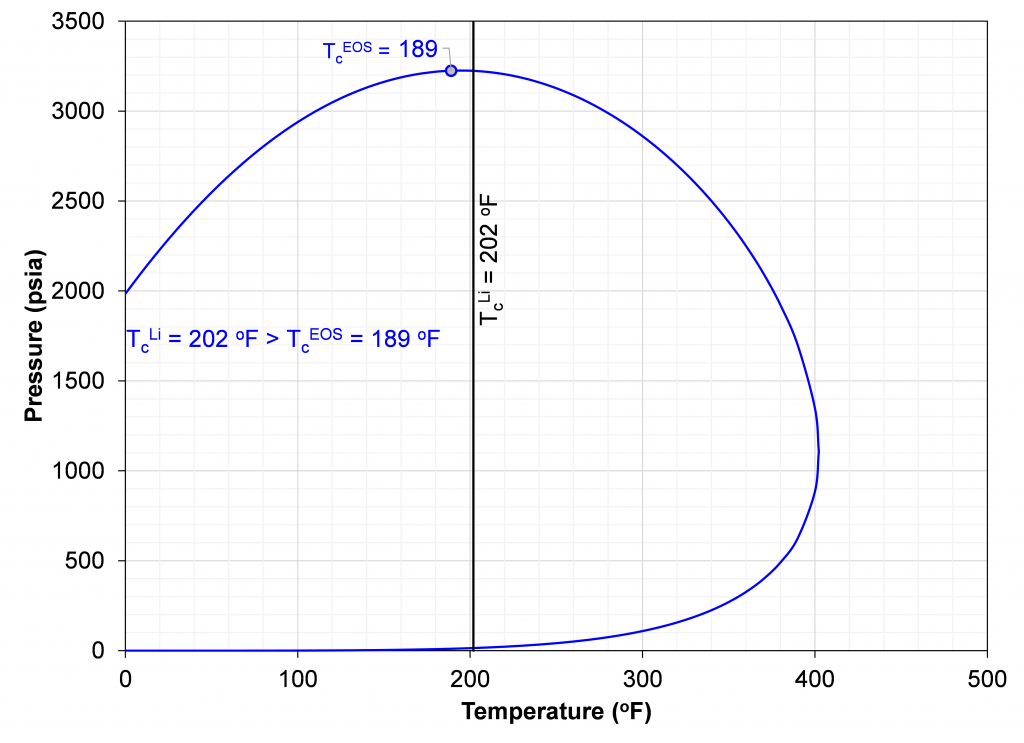

TcLi is then compared with grid cell temperature T. If T> TcLi, the single phase is labelled as gas and vice versa for oil. To show the difference between TcLi and EOS-based critical temperature of zi (TcEOS), a three component EOS model was used to calculate TcLi and TcEOS for an arbitrary composition zi. Calculation of TcEOS requires a search of the true critical point (Tc, pc) of zi using the EOS model, where K-values of all components converge to a value of one. Figure 1 shows the difference between the two types of critical temperatures for composition zi.

A simple 1D vertical E300 model was setup with reservoir temperature T equal to 200oF, constant composition zi and initial reservoir pressure equal to 5000 psia (far greater than saturation pressure 3224 psia). With default Li correlation method, E300 predicts oil phase everywhere in the model initially because T=200oF< TcLi =202oF. However, the composition should be single-phase gas because TcEOS (the “true” critical temperature) is less than T. Wrong single-phase labeling with Li correlation usually occurs for near critical fluid systems such that when TcLi and TcEOS are in close proximity of reservoir temperature T. For other fluid systems, where critical temperatures (both TcLi and TcEOS) are far removed from T, this is not usually a problem.

E300 allows tuning of the Li correlation with FACTLI keyword. The FACTLI value is multiplied with TcLi to modify it such that the predicted phase is correct during the initialization of the model. If FACTLI value is not defined by the user and a compositional gradient exist in the reservoir (defined by COMPVD or ZMFVD), E300 calculates the FACTLI value automatically to make sure all initial compositions above the user defined GOC are predicted as gas phase and below the GOC as oil phase[1]. The tuned Li correlation makes sure that TcLi = TcEOS only for initial composition defined at GOC depth. For all other initial compositions with depth zi(D), TcLi may not equal to TcEOS, however TcLi is greater than T for all zi(D) above the GOC and less than T for all zi(D) below GOC, ensuring right phase definition at time zero in the model. Because E300 automatic tuning to Li correlation ensures TcLi = TcEOS for GOC composition, the automatic tuning only works if compositional equilibration option 1 is selected in item 10 of keyword EQUIL (i.e. single phase near critical system with under-saturated GOC) and the GOC is set within the reservoir. It is also possible to define multiple FACTLI values specific to each equilibration region. The tuned Li correlation may guarantee the right phase definitions during initialization but does not guarantee that all zi values originate with depletion/gas injection will have right single-phase definition.

Inaccurate phase labeling at time zero may affect fluid inplace calculations in the model. Accuracy of fluid inplace numbers depend on the accuracy of (a) hydrocarbon pore volume calculation (HCPV) and (b) calculated PVT properties i.e. solution GOR (or OGR) and formation volume factor (FVF) for all zi(D) values. PVT properties for any zi are only a function of the EOS model and the surface process conditions and are completely independent of zi being labelled as gas or oil in the model. HCPV can be affected slightly due to wrong phase labeling if Pcow and Pcgw are not equal, leading to small differences in fluid inplace results. The results of dynamic simulation can also be affected by wrong phase labeling of single-phase cells. For instance, this can happen if the end points of gas and oil relative permeability curves are not the same such that Krg and Kro at 1-Swi.

E300 allows EOS-based (or saturation pressure based) phase labeling of single-phase cells by activating PSSTA keyword in RUNSPEC section. The keyword only works during dynamic simulation (i.e. t > 0) and cause increase in the run time. E300 still uses Li correlation for single-phase labeling at time zero even if this keyword is activated. To get EOS-based phase labeling for all initial (t=0) compositions in the model, the model can be run for a very small time step without any production from the reservoir.

Accurate (EOS-based) single-phase labeling can be important in compositional reservoir modeling for various reasons discussed previously. This is especially important for near critical fluid systems either present initially in the model or originate in the reservoir with time for example due to a gas injection process. Therefore, it is recommended to run the compositional model atleast once with EOS-based phase labeling to quantify (a) the effect of wrong phase labeling (if exists) and (b) additional run-time required for the simulation. Based on the results of (a) and (b), it will be possible to decide if EOS-based single-phase labeling is important and needs to be accounted for in the model or not.

[1] For accurate phase labeling (at time zero in the model) with the tuned Li correlation for an undersaturated GOC fluid system for all zi(D) values, it is important to know the exact GOC depth and the GOC composition.

Learn more about our consulting capabilities

###

Global

Curtis Hays Whitson

curtishays@whitson.com

Asia-Pacific

Kameshwar Singh

singh@whitson.com

Middle East

Ahmad Alavian

alavian@whitson.com

Americas

Mathias Lia Carlsen

carlsen@whitson.com

About whitson

whitson supports energy companies, oil services companies, investors and government organizations with expertise and expansive analysis within PVT, gas condensate reservoirs and gas-based EOR. Our coverage ranges from R&D based industry studies to detailed due diligence, transaction or court case projects. We help our clients find the best possible answers to complex questions and assist them in the successful decision-making on technical challenges. We do this through a continuous, transparent dialog with our clients – before, during and after our engagement. The company was founded by Dr. Curtis Hays Whitson in 1988 and is a Norwegian corporation located in Trondheim, Norway, with local presence in USA, Middle East, India and Indonesia