Author: Mathias Lia Carlsen

* This is a short-version of URTeC-2869-MS that was presented on the URTeC 21 July 2020. The manuscript can be found attached to this blog post.

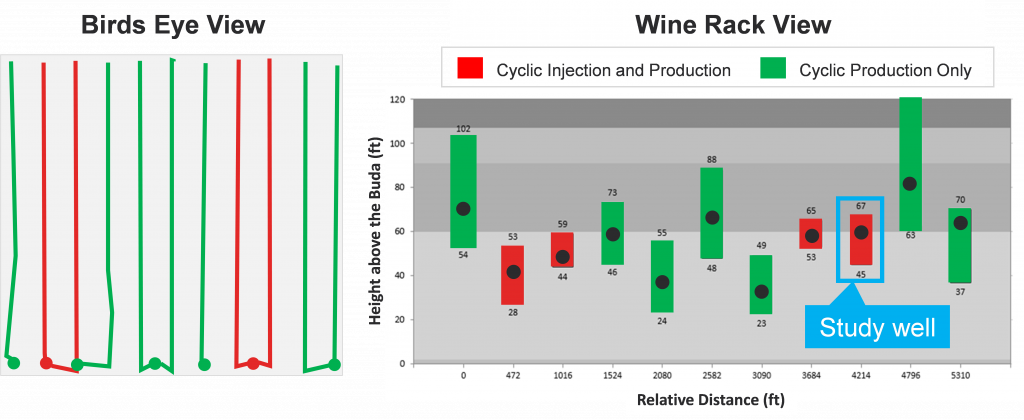

The HnP project studied in this paper involves a group of 11 wells configured such that four of the wells were subjected to cyclic injection and production (i.e. HnP), while the remaining seven wells were subjected to cyclic production (i.e. shut in during injection periods). The configuration is shown in Fig. 1.

Most of the wells came online in early 2015, and the HnP process started in late 2018 (i.e. a 3.5-year primary depletion period prior to HnP implementation). The first 15 injection periods lasted for 15-45 days, and average injection rates were 14-16 MMscf/D. Cumulative injected volume per cycle ranged from 200 to 600 MMscf. A “representative” injection-gas composition for this project is 75 mol% C1, 13 mol% C2, 5 mol% C3, and 7 mol% C4+, with some variation in time.

During the injection (huff) periods, gas was injected in one or two wells depending on the cycle. Because gas was observed in the neighboring producers during injection (well spacing approximately 500 ft), it was decided to shut in these wells while injecting to mitigate gas circulation within connected fractures and allow for pressure buildup. When the wells were put back on production (puff), increased oil production rates were observed (compared to the baseline forecast) in the four HnP wells and neighboring producers.

Characteristics of HnP Produced Wellstreams—Field Observations

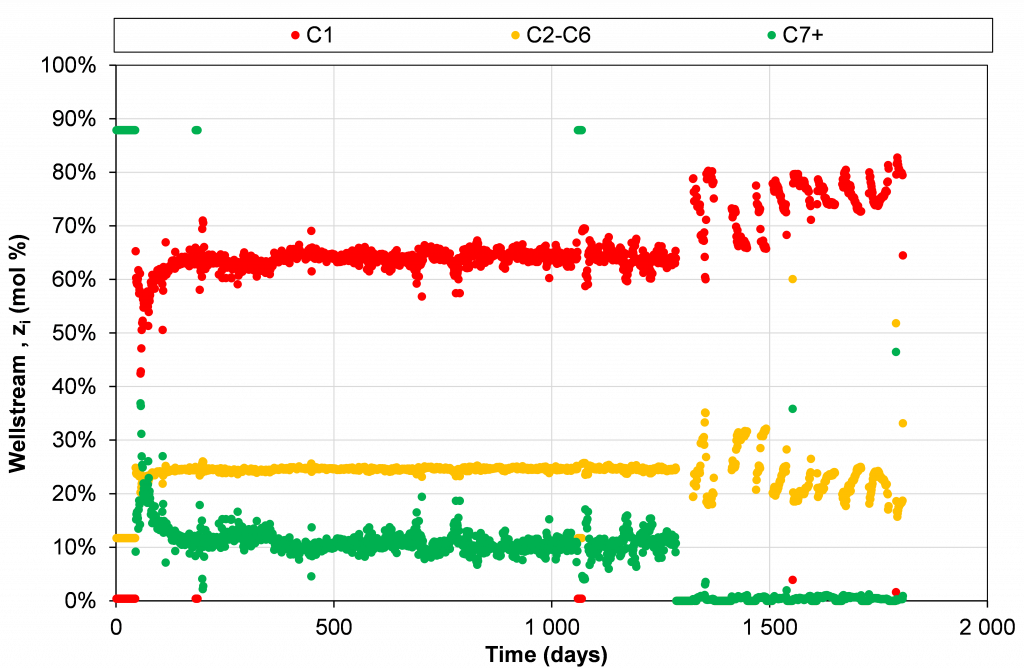

The production and fluid sampling data were successfully used to predict daily wellstream compositions for the study well that was subjected to cyclic gas injection. Fig. 2 shows the variation over time for C1, C2-C6 (grouped together), and C7+ in the measured wellstream composition. One can clearly see the compositional differences before and after gas HnP was implemented. Before implementation, the C1 content of the wellstream was ~65 mol%, the C2-C6 content was ~25 mol%, while C7+ amounted to ~10 mol%. After implementation, the C1 content of the wellstream varied between 65-80 mol%, the C2-C6 content varied between 15-30 mol% and the C7+ content varied between 0.25-1 mol%. The large time-variations observed for the producing wellstream composition underlines the compositional sensitivity of the gas HnP process. It is worth noting that the compositional changes observed in a single HnP production period are larger than the compositional changes observed over the entire primary-depletion period. The general trends over time for the wellstream composition show increasing C1 amount, decreasing C2-C6 amount, and an inconclusive trend for the C7+ amount.

A Mix of Injected Gas & Reservoir Fluid

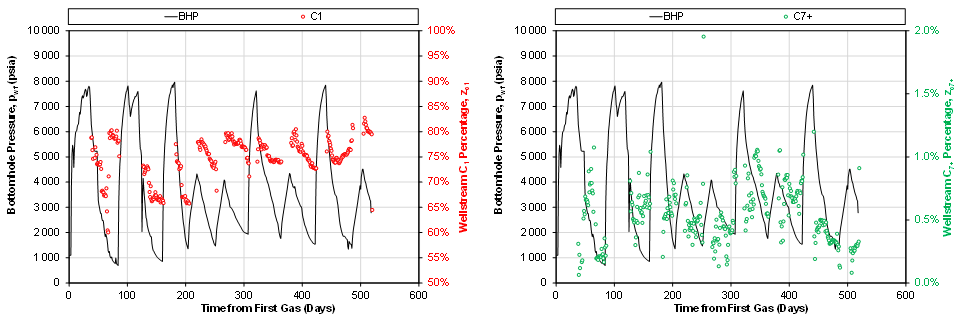

Fig. 3 shows a “zoomed-in” view of the predicted C1 and C7+ wellstream composition versus time for the gas HnP well. One key observation from this figure is that the produced gas at the very early part of the production period is not just the injected gas, which contains less than 0.2 mol% C7+, but a mix of the injected gas and reservoir fluid, resulting in a wellstream C7+ content of ~0.5-1 mol%. Attaining an increased amount of C7+ components in the returning wellstream (i.e. enrichment of the injection-gas composition) is the main premise for increased oil recovery by the HnP process, as these heavier components turn into stock-tank oil when the wellstream is processed at the surface.

Summary

The wellstreams produced during the HnP flowback (production period) suggest that the produced fluids are a mix of the injected gas and the reservoir oil. Attaining an increased amount of C7+ components in the returning wellstream (i.e. enrichment of the injection-gas composition) is the main premise for increased oil recovery by the HnP process, as these heavier components turn into stock-tank oil when the wellstream is processed at the surface.

Learn more about our consulting capabilities

###

Global

Curtis Hays Whitson

curtishays@whitson.com

Asia-Pacific

Kameshwar Singh

singh@whitson.com

Middle East

Ahmad Alavian

alavian@whitson.com

Americas

Mathias Lia Carlsen

carlsen@whitson.com

About whitson

whitson supports energy companies, oil services companies, investors and government organizations with expertise and expansive analysis within PVT, gas condensate reservoirs and gas-based EOR. Our coverage ranges from R&D based industry studies to detailed due diligence, transaction or court case projects. We help our clients find the best possible answers to complex questions and assist them in the successful decision-making on technical challenges. We do this through a continuous, transparent dialog with our clients – before, during and after our engagement. The company was founded by Dr. Curtis Hays Whitson in 1988 and is a Norwegian corporation located in Trondheim, Norway, with local presence in USA, Middle East, India and Indonesia