Author: Mathias Lia Carlsen

* This is a snippet from SPE-199982-MS that was presented on the SPE Canada Unconventional Resources Conference held virtually in 2020. The full manuscript can be found attached to this blog post.

Decreasing CGRs are observed while flowing bottomhole pressures are above the (apparent) saturation pressure in several unconventional basins throughout North America such as Eagle Ford and Duvernay. Different reservoir related explanations have been proposed, among which the most popular are:

- Fluid heterogeneity (Whitson et al. 2018)

- Gas adsorption (Walker et al. 2017)

- Pore confinement effects (Devegowda et al. 2012; Jin et al. 2016)

Even though there are several working reservoir related theories, there seem to be a lack of consensus in the industry on the primary drivers behind this characteristic. General agreement, however, seems to be established around it being more prominent for leaner fluids (lower CGRs) than richer fluids (higher CGRs). Other than that, there seem to be several ways to mimick this behavior physically and with simulation, which leaves this to be a somewhat non-unique exercise without large amounts of high-quality lab and field data supporting either theory. What further complicates this exercise, is that operational effects can have a significant impact on producing CGRs – even if the producing wellstream composition is constant[1]– such as,

- Separator gas blowby (gas “carryover”)

- Different early time (handle lots of water) and late time surface process (handle less water)

- Significant changes in separator conditions (Tsep and psep) – as discussed below in this post

Surface volumes are “Path Dependent”. The relationship between reservoir volumes and surface volumes (Bo, Rs | bgd, rs) is “path dependent”. For instance, for any given petroleum fluid, a three-stage separator process yields more surface liquid than a single-stage separator process. In other words, how much of the reservoir fluid that translates into surface oil and surface gas is related to the compositional path the components are subject to from reservoir to sales. For petroleum engineering purposes, this “path” is generally determined by the surface process, i.e. typically i) number of surface separator stages and ii) pressure and temperature of each stage.

Common Process Conversion. If the surface process separator conditions are changing significantly over time, a “correction” to a set of constant separator conditions might be needed for

- Consistent well-to-well performance comparison

- Consistent usage of black oil tables in history matching (using RTA/PTA or res. simulation)

- Consistent analysis of CGR performance over time

The correction is referred to as common process conversion, as we “convert” the rates obtained from changing separator conditions to a “common” surface process (i.e. fixed temperature and pressure in each stage).

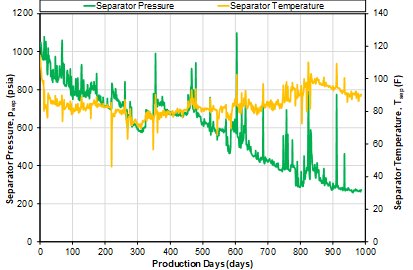

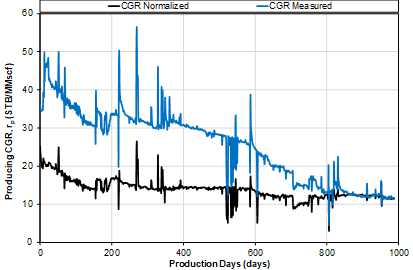

Fig. 1 shows common process conversion applied to a well in the Eagle Ford producing from a lean gas condensate fluid system that shows considerable CGR decrease from day 1 (above the apparent saturation pressure). Separator pressures are decreasing from 1000 psia to 250 psia in ~1000 days, as seen in Fig. 1a. If the changing separator conditions are not accounted for, it looks like the CGR decreases significantly from day 1. However, after applying common process conversion, much of the relative decrease in CGR is reduced, as seen in Fig. 1b. If we had not performed the correction, we would potentially attribute this decrease in CGR above the saturation pressure to some other physical process. This is a good example of when common process conversion has a large impact in general, which is expected as the separator conditions are changing significantly, and the fluid system is relatively lean.

|  |

| Fig. 1a. Separator temperature and pressure for a lean gas condensate well in the Eagle Ford. | Fig. 1b. CGR normalization applied to a lean gas condensate well in the Eagle Ford. |

[1] Producing compositions are constant while flowing BHPs are above the saturation pressure of the reservoir fluid (pwf > psat)

References

[1] Devegowda, D., Sapmanee, K., Civan, F., & Sigal, R. F. (2012, January 1). Phase Behavior of Gas Condensates in Shales Due to Pore Proximity Effects: Implications for Transport, Reserves and Well Productivity. Society of Petroleum Engineers. doi:10.2118/160099-MS

[2] Jin, Z., & Firoozabadi, A. (2016, February 1). Thermodynamic Modeling of Phase Behavior in Shale Media. Society of Petroleum Engineers. doi:10.2118/176015-PA

[3] Walker, G., Branter, T., & Miller, P. (2017, February 15). Adsorbed Gas Composition, and its Impact on Early Time Production. Society of Petroleum Engineers. doi:10.2118/185045-MS

[4] Whitson, C. H., Alqahtani, F. M., & Chuparova, E. (2018, August 9). Fluid Heterogeneity on a Well-Box Scale in Tight Unconventional Reservoirs. Unconventional Resources Technology Conference. doi:10.15530/URTEC-2018-2882502

Learn more about our consulting capabilities

###

Global

Curtis Hays Whitson

curtishays@whitson.com

Asia-Pacific

Kameshwar Singh

singh@whitson.com

Middle East

Ahmad Alavian

alavian@whitson.com

Americas

Mathias Lia Carlsen

carlsen@whitson.com

About whitson

whitson supports energy companies, oil services companies, investors and government organizations with expertise and expansive analysis within PVT, gas condensate reservoirs and gas-based EOR. Our coverage ranges from R&D based industry studies to detailed due diligence, transaction or court case projects. We help our clients find the best possible answers to complex questions and assist them in the successful decision-making on technical challenges. We do this through a continuous, transparent dialog with our clients – before, during and after our engagement. The company was founded by Dr. Curtis Hays Whitson in 1988 and is a Norwegian corporation located in Trondheim, Norway, with local presence in USA, Middle East, India and Indonesia