By Mathias Lia Carlsen, July 2021

*This is a short-version of URTeC 5016 by Mydland, Carlsen and Whitson found attached to this article.

Gas EOR in Tight Unconventionals

The gas-based Huff-n-Puff (HnP) process is currently the dominating EOR process in tight unconventionals. This has happened as a result of operators looking to find new ways of increasing the production from their acreage, and several field implementations of the HnP process that have claimed success in doing so. Although the process has been studied largely the last years, there are still several aspects of the HnP process that are not yet fully understood, particularly its complex nature regarding the fluid phase behavior.

To help increase the understanding of the HnP process from a fluid perspective, we suggest a novel PVT experiment that captures the key characteristics of the HnP process, and provide all relevant stakeholders with the key performance indicator (KPI) that we refer to as the gas HnP recovery efficiency, defined as “incremental volume of stock-tank oil (STO) produced per volume of surface gas injected” (which in field terms is denoted incremental STB of oil produced per MMscf injected).

The HnP Process

The gas HnP process is fundamentally different from a conventional/traditional displacement process. Conventional gas EOR is based on a configuration of designated injection- and production wells, whereas the HnP process is based on a single well in which injection and production are performed cyclically.

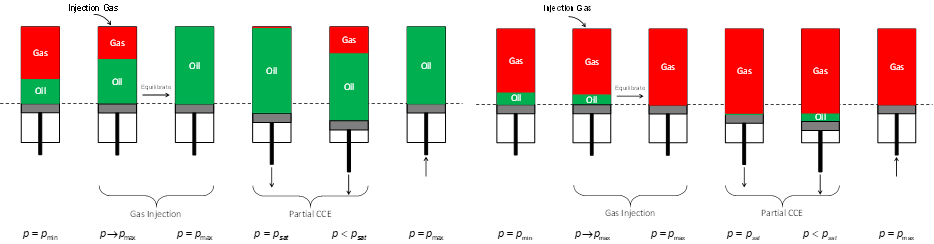

Carlsen et al. (2019), and Mydland et al. (2020), describe in detail why the HnP process is not a displacement process, and therefore how the conventional EOR theory becomes irrelevant. The HnP process achieves recovery by mixing the injected gas and the reservoir fluid by either vaporization of reservoir-fluid components into the gas phase when the system is in two-phase equilibrium, or by dissolving of the injected gas into the reservoir fluid when the system is single phase.

The HnP PVT Experiment

For conventional gas EOR processes, a central part of planning involves estimating the multi-contact minimum miscibility pressure (MMPMC), as this is the lowest pressure for which the displacement front can sustain miscible displacement efficiency. As a result, multiple experiments have been suggested to get an estimate of the MMPMC. The traditional, and most reliable, is the slimtube test (Yellig and Metcalfe 1980, Dindoruk et al. 2020). Other less accurate experiments have been introduced on the argument of being less time consuming and thus cheaper to perform than the slimtube (Christiansen and Haines 1987, Rao 1987).

That is why we suggest this novel fluid experiment that captures the key characteristics of the gas HnP process, which are i) injection periods with associated pressure build up, ii) production periods with associated pressure drawdown, iii) a cyclic nature, and iv) a way of quantifying oil recovery versus number of cycles and/or volume (moles) of gas injected. Because we look at fluids only, and are not relying on small residual amounts left in core plugs, we obtain accurate measurements and tracking of the material balance throughout the experiment.

We emphasize that the proposed HnP PVT experiment assumes ideal conditions. It does not account for aspects such as time, spatial pressure variations, incomplete mixing, diffusion/dispersion, confinement/containment issues, fluid heterogeneity, and fracture/matrix flow. This means that the experiment provides an estimate of the HnP performance that represents an upper bound of what to expect in field.

All the technical details of the experiment can be found here

References

Carlsen, M., Whitson, C., Dahouk, M. M., Younus, B., Yusra, I., Kerr, E., … Mydland, S. (2019a, July 31). Compositional Tracking of a Huff-n-Puff Project in the Eagle Ford. Unconventional Resources Technology Conference. doi:10.15530/urtec-2019-539

Dindoruk, Birol , Johns, Russell , and Franklin M. Orr. “Measurement and Modeling of Minimum Miscibility Pressure: A State-of-the-Art Review.” SPE Res Eval & Eng 24 (2021): 367–389. doi: https://doi.org/10.2118/200462-PA

Mydland, Stian , Yusra, Ilina , Whitson, Curtis Hays, Dahouk, Mohamad Majzoub, and Mathias Lia Carlsen. “Gas EOR Processes in Tight Unconventionals.” Paper presented at the SPE Improved Oil Recovery Conference, Virtual, August 2020a. doi: https://doi.org/10.2118/200396-MS

Tovar, Francisco D., Barrufet, Maria A., and David S. Schechter. “Enhanced Oil Recovery in the Wolfcamp Shale by Carbon Dioxide or Nitrogen Injection: An Experimental Investigation.” SPE J. 26 (2021): 515–537. doi: https://doi.org/10.2118/204230-PA

Rao, Dandina N. 1997. A new technique of vanishing interfacial tension for miscibility

determination. Fluid Phase Equilibria 139 (1): 311-324. http://www.sciencedirect.com/science/article/pii/S0378381297001805

Yellig, W.F., and R.S. Metcalfe. “Determination and Prediction of CO2 Minimum Miscibility Pressures (includes associated paper 8876 ).” J Pet Technol 32 (1980): 160–168. doi: https://doi.org/10.2118/7477-PA

###

Learn more about our consulting capabilities

Global

Curtis Hays Whitson

curtishays@whitson.com

Asia-Pacific

Kameshwar Singh

singh@whitson.com

Middle East

Ahmad Alavian

alavian@whitson.com

Americas

Mathias Lia Carlsen

carlsen@whitson.com

About whitson

whitson supports energy companies, oil services companies, investors and government organizations with expertise and expansive analysis within PVT, gas condensate reservoirs and gas-based EOR. Our coverage ranges from R&D based industry studies to detailed due diligence, transaction or court case projects. We help our clients find the best possible answers to complex questions and assist them in the successful decision-making on technical challenges. We do this through a continuous, transparent dialog with our clients – before, during and after our engagement. The company was founded by Dr. Curtis Hays Whitson in 1988 and is a Norwegian corporation located in Trondheim, Norway, with local presence in USA, Middle East, India and Indonesia