We wanted to highlight and share a paper we think everyone in tight unconventionals should read, namely URTeC 2670034, “Sampling a Stimulated Rock Volume: An Eagle Ford Example” by Kevin Raterman and Helen Farrell et al. The paper is a few years old now, but has fundamentally changed the mental model for how unconventional rocks breaks … at least for many of us!

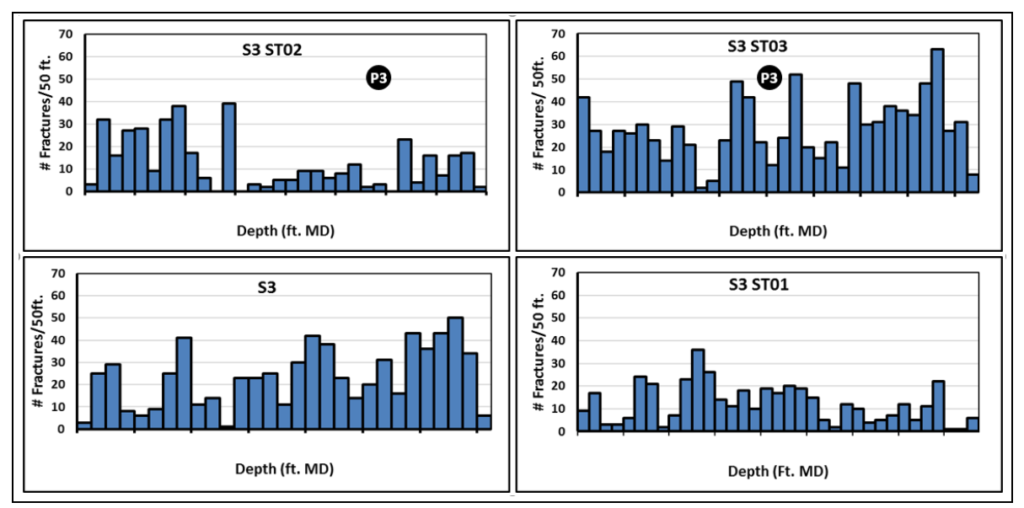

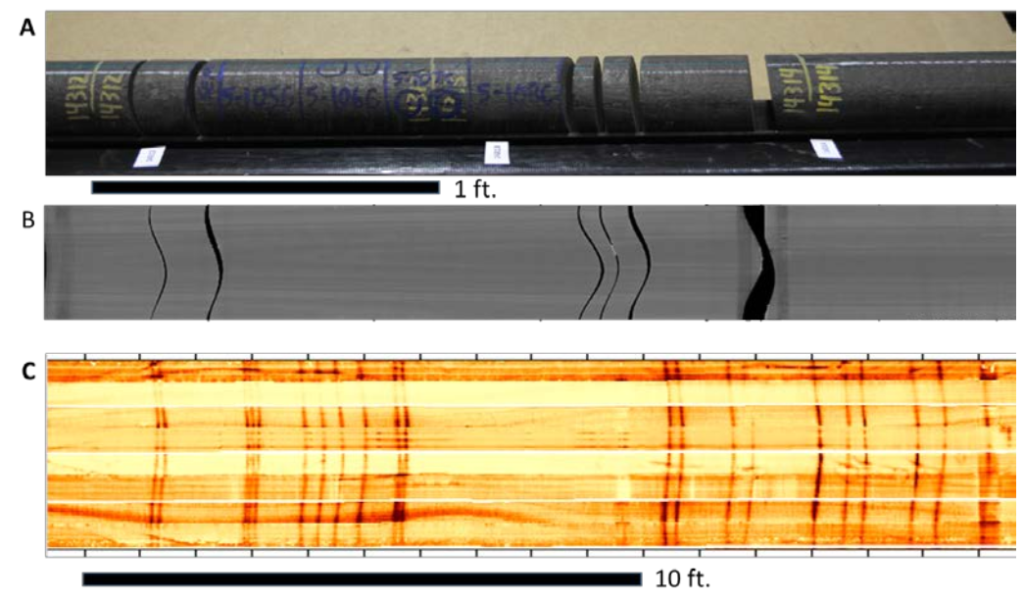

Between 2014 and 2016, ConocoPhillips conducted a pilot study in the Eagle Ford Formation in Texas to examine the physical characteristics of the reservoir stimulation caused by hydraulic fracturing. The study used five deviated wells that were drilled adjacent to a multistage, stimulated horizontal producer. The data collected from the study, including core samples, borehole images, tracer logs, and pressure data, showed that the stimulation effectively broke the reservoir rock and created a complex array of hydraulic fractures. Some of these fractures extended over interwell distances of more than 1,000 feet, but the data also indicated that proppant transport was limited to distances less than 75 feet from the producer, suggesting that the stimulated rock volume (SRV) might be larger than the volume of rock that can be effectively drained. Overall, the pilot established the limited presence of pre-existing natural fractures in the area and allowed for the determination of the spatial characteristics of the stimulation.

The operational success of a pilot study conducted by ConocoPhillips in the Eagle Ford Formation in Texas demonstrated that the stimulated rock volume (SRV) in a shale can be drilled and sampled and that useful information can be gathered. The main outcome of the study was an improved understanding of the complex characteristics of the SRV. Key observations and conclusions from the study include: permeability enhancement is achieved through discrete fractures rather than distributed matrix damage; the hydraulic fractures form swarms that, in some cases, show a relationship to cluster spacing; the hydraulic fractures are perpendicular to the minimum horizontal in-situ stress and are steeply dipping rather than vertical; the SRV is on the order of two to three times as broad laterally as it is tall; the stimulation efficiently fractured the formation, but proppant emplacement was less successful; DAS (distributed acoustic sensing) can be used as a fracture detection tool and indicates that some fractures propagate over long distances; there is no direct statistical relationship between sampled hydraulic fracture density and microseismic event density; and the stimulation monitoring by DTS (distributed temperature sensing) and DAS showed that not all perforation clusters received equal volumes of fluid. These observations have led ConocoPhillips to reexamine its approach to completion design, well design, and well spacing and stacking assumptions, and have highlighted significant challenges in modeling fracture propagation, predicting production performance, and understanding long term multi-well interactions.

Want to learn more? Download the paper →→→here←←←.

###

Learn more about our software products

Global

Curtis Hays Whitson

curtishays@whitson.com

Asia-Pacific

Kameshwar Singh

singh@whitson.com

Middle East

Ahmad Alavian

alavian@whitson.com

Americas

Mathias Lia Carlsen

carlsen@whitson.com

About whitson

whitson supports energy companies, oil services companies, investors and government organizations with expertise and expansive analysis within PVT, gas condensate reservoirs and gas-based EOR. Our coverage ranges from R&D based industry studies to detailed due diligence, transaction or court case projects. We help our clients find the best possible answers to complex questions and assist them in the successful decision-making on technical challenges. We do this through a continuous, transparent dialog with our clients – before, during and after our engagement. The company was founded by Dr. Curtis Hays Whitson in 1988 and is a Norwegian corporation located in Trondheim, Norway, with local presence in USA, Middle East, India and Indonesia.